Metal Wire Mesh

PACO's origin and key competence is the production of high-precision metal wire mesh, often referred to as stainless steel mesh or metal cloth. The in-house metal wire-weaving mills produce a comprehensive range of cloth types from different materials and wire thicknesses. Depending on the type of cloth, widths of up to 3.2 m can be produced. Cloths differ with regard to the type of weave, mesh shape and width, as well as material, mechanical properties of the wires and wire diameter. The classification of mesh is based on specific standards, such as DIN EN ISO 9044 for square meshes and DIN EN ISO 3310 for test sieves. Over the years, further company standards have been developed, especially in the area of special mesh types, where the expertise and experience of the cloth manufacturer is particularly important. In addition to the expertise of the weavers, the right choice of weaving wires and the capabilities of the frames, harnesses and looms are essential to ensure robust fabric quality.

Several hundred specifications are always in stock. Special meshes are produced with very short lead times thanks to our advanced and flexible production technology. Uncompromising quality assurance, from the initial inspection of the wires used to inline inspections and 100% final acceptance of all meshes, provides a reliable basis for high-quality screen and filter products as well as excellent screening and filtration results. We are constantly examining the mesh testing technology available on the market within the context of our processes. For the past two years, we have been using the MeshInspector in all of our weaving mills.

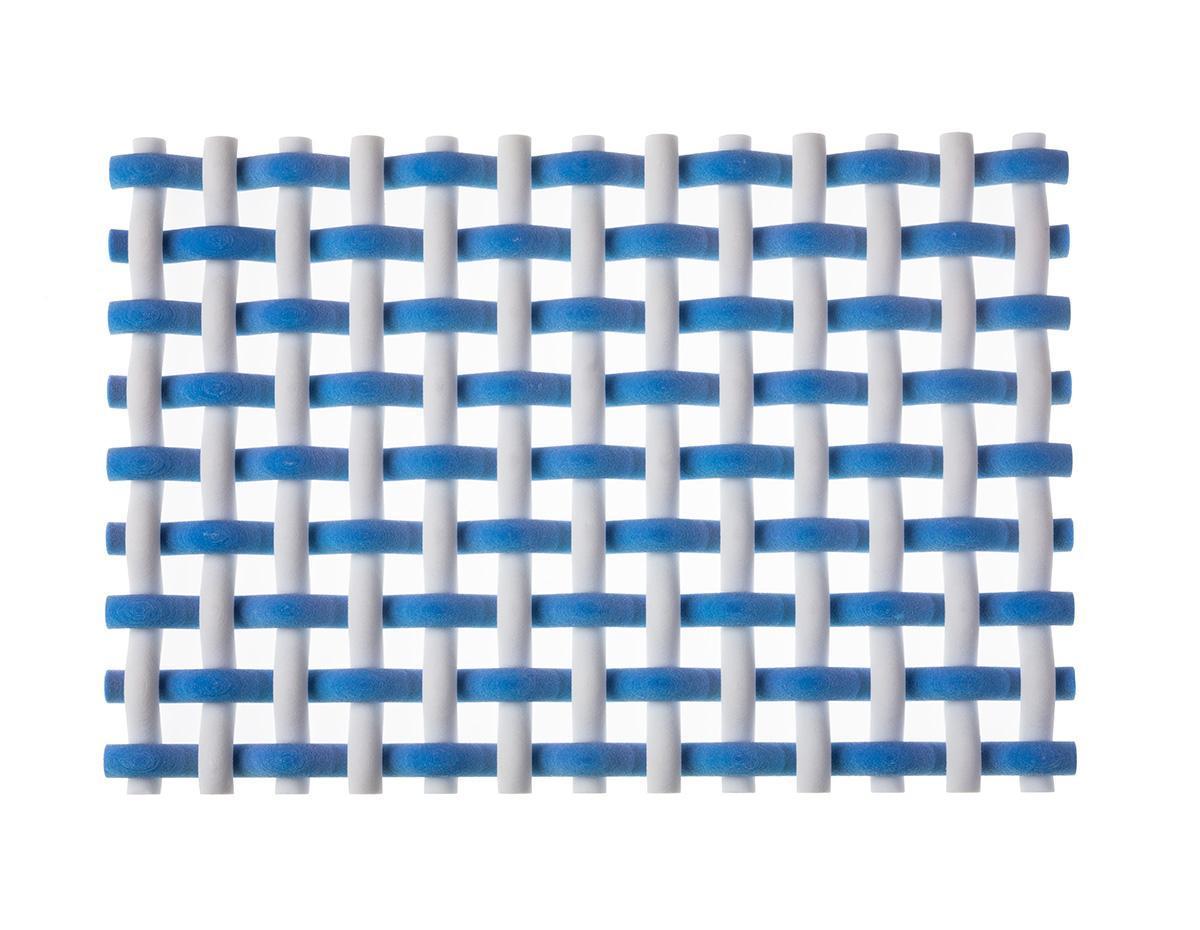

Plain or Linen Weave

more

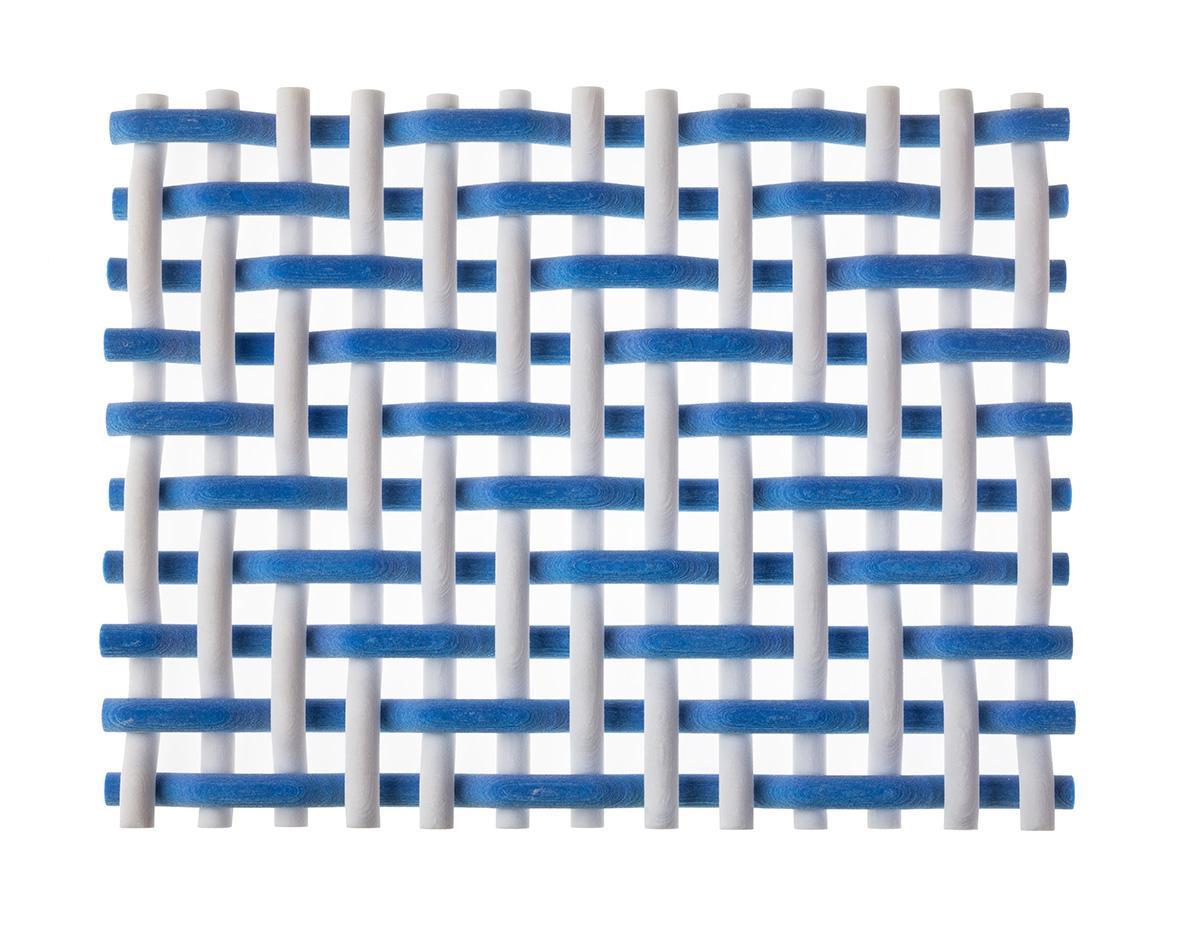

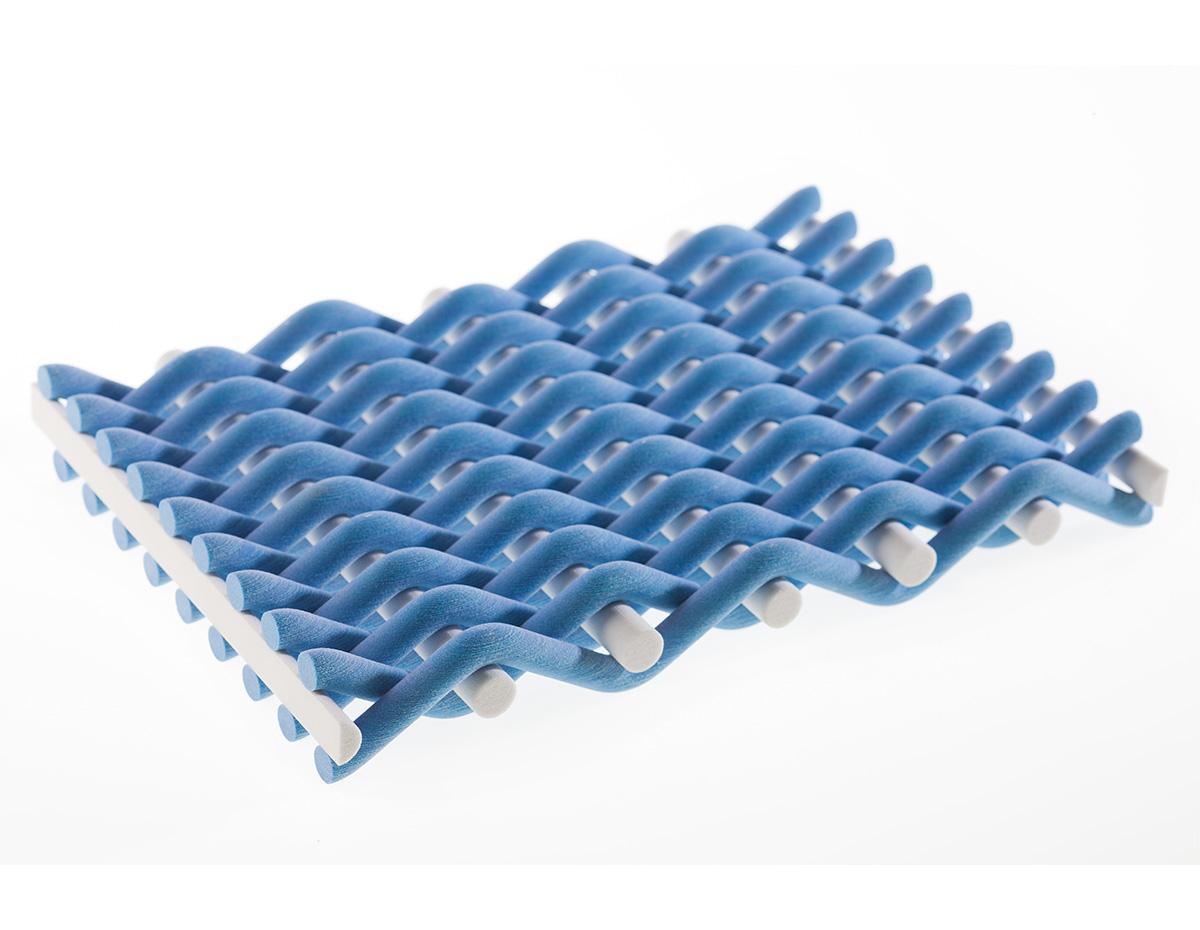

Twilled Weave

more

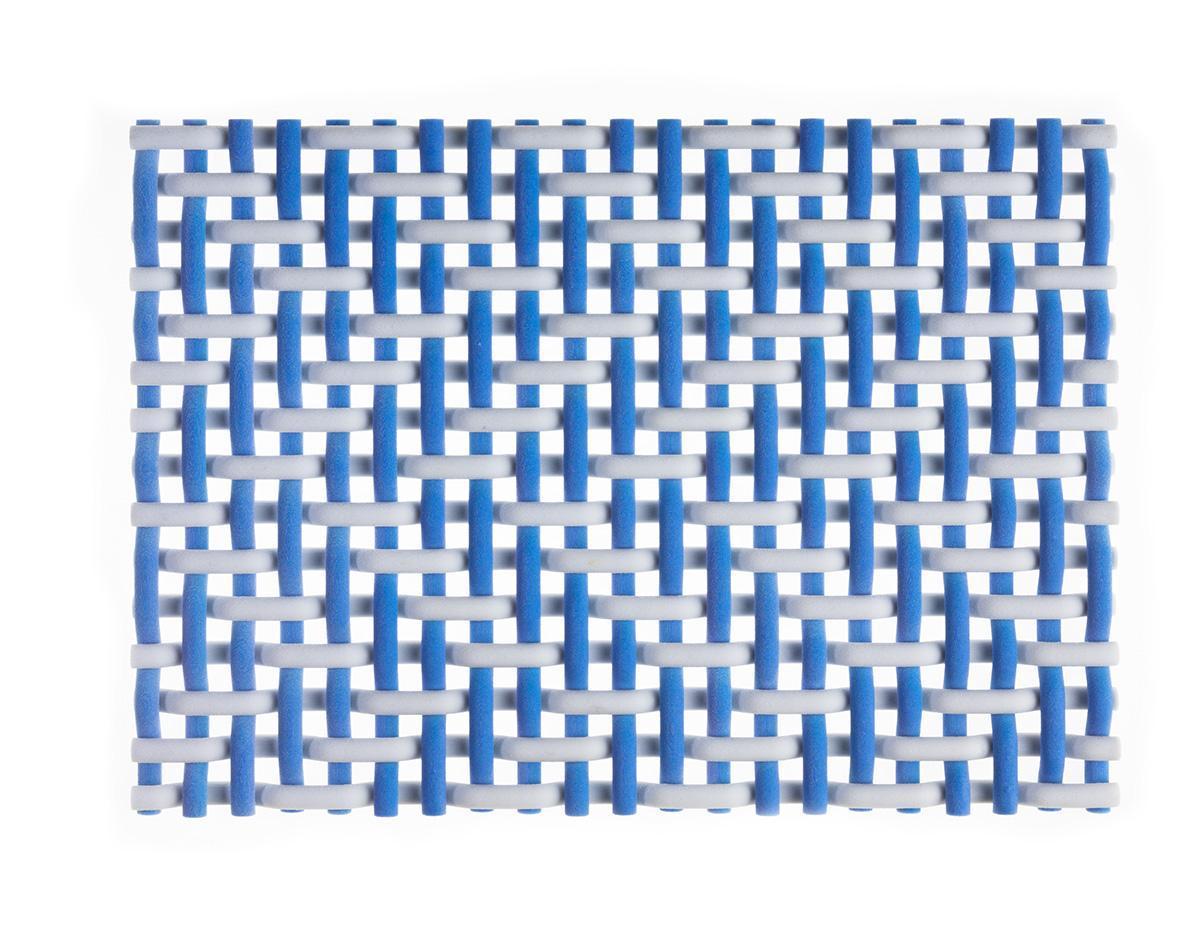

Herringbone Twilled Weave

more

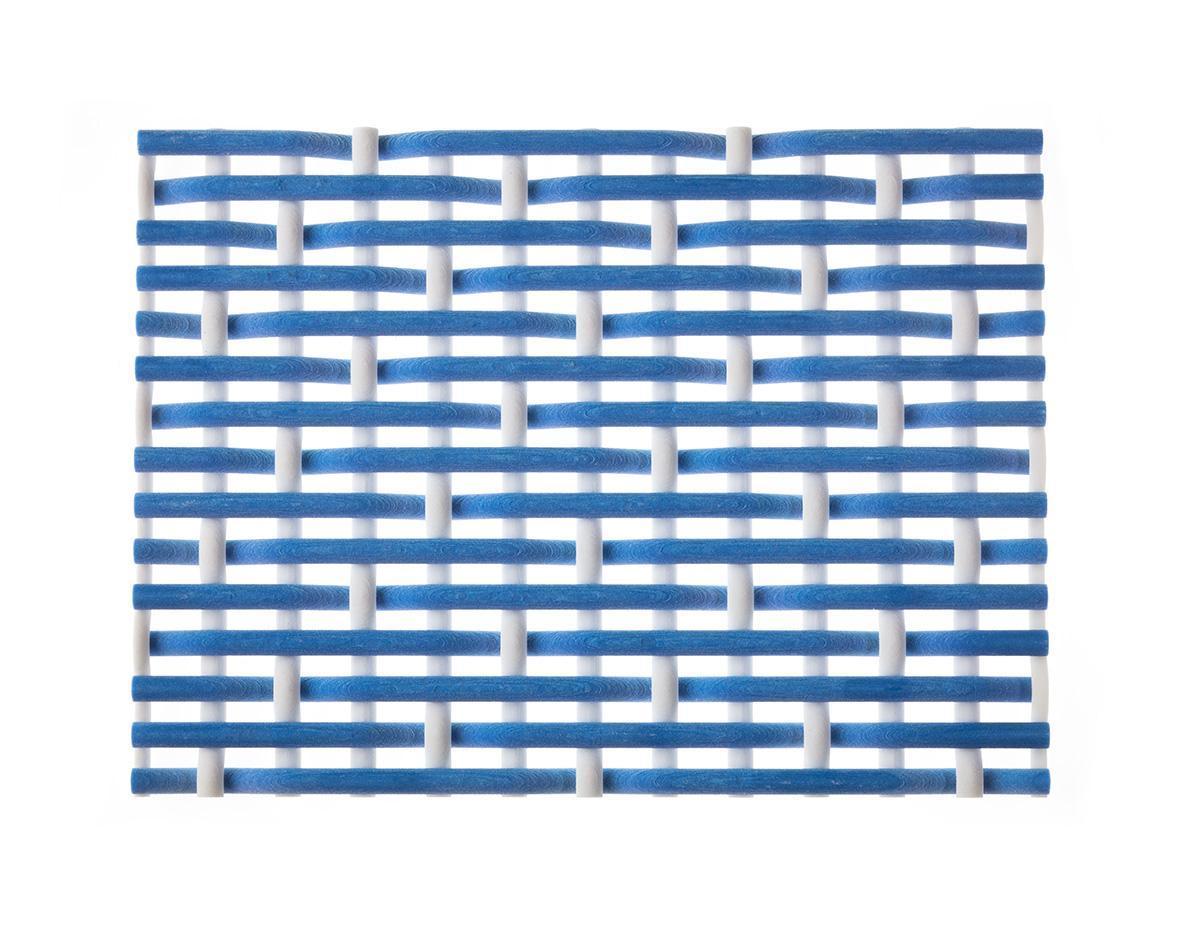

5-Shaft Twilled Weave

more

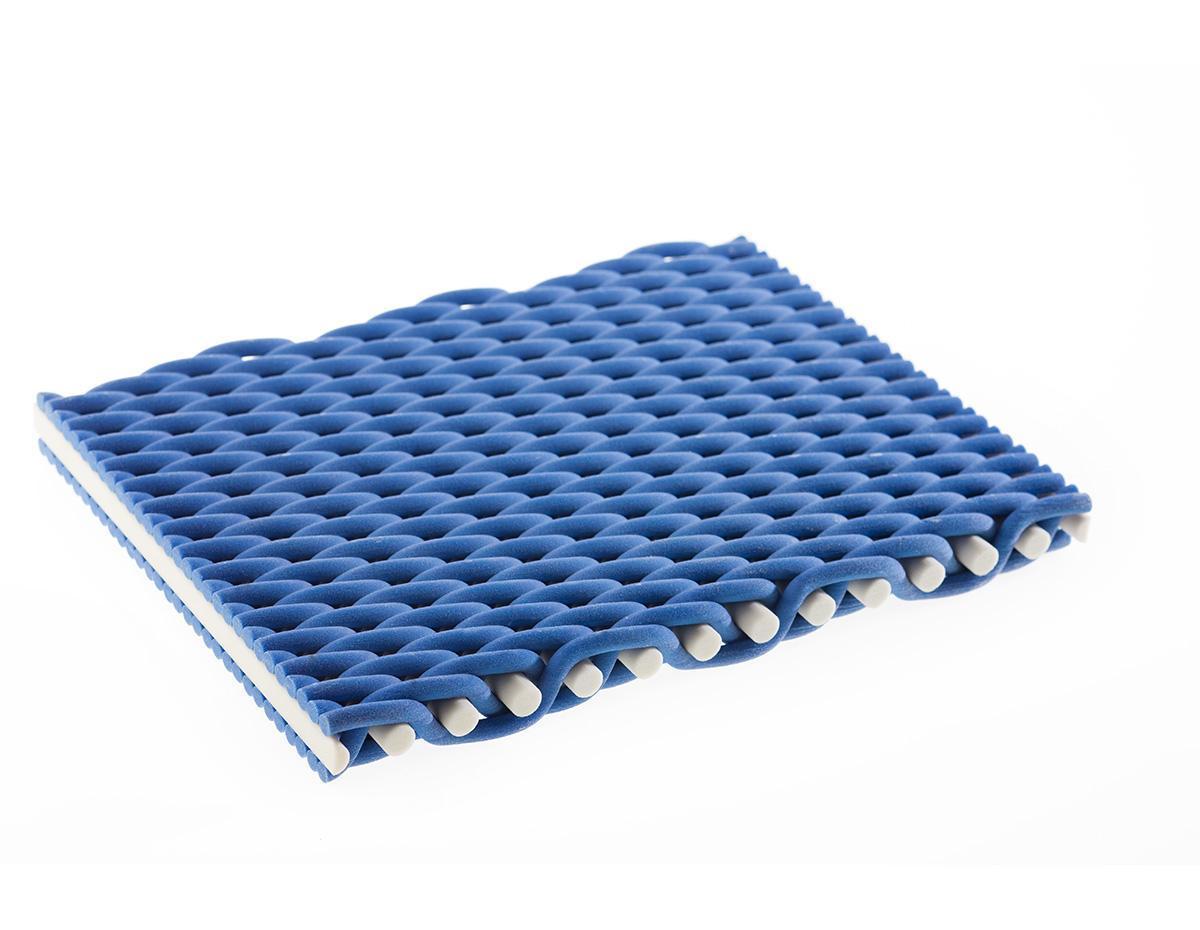

Plain Dutch Weave

more

Plain Dutch Weave Duplex

more

Plain Dutch Weave Highflow

more

Dutch Twilled Weave

more

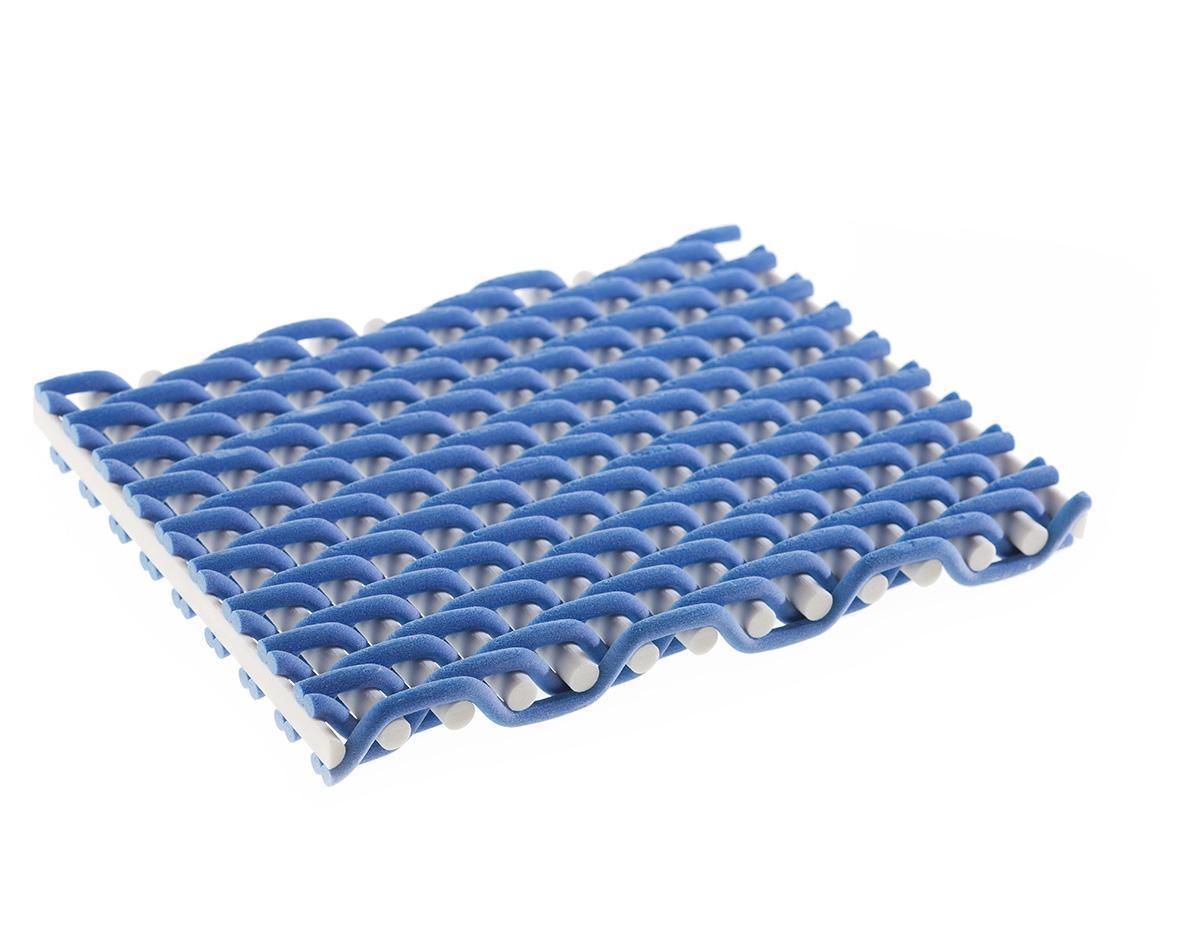

Broad-Mesh Twilled Weave

more

Reverse Dutch Weave

more

Reverse Dutch Twilled Weave

moreMaterials

The prerequisite for successful wire cloth production is the correct selection of weaving wire quality. These are primarily dependent on the technical properties of the materials used. Not every material is available in all wire diameters and with all technical requirements. This is why an understanding of the correct choice of material and cloth quality is of fundamental importance.

The following materials are generally suitable for the production of metal wire cloth.

- Steels, incl. stainless steels

- Aluminium and aluminium alloys

- Copper and copper alloys

- Nickel and nickel alloys

- Titanium and titanium alloys

We will be very pleased to clarify on request or in a one-to-one technical discussion which material is best suited for a specific application.

Specifications

The properties and performance characteristics of PACO metal wire cloths are as diverse as the potential applications and needs of our customers. We mainly process stainless steel wires made of the materials 1.4301, 1.4401, 1.4541, 1.4571, 1.4550 – to name just a few.

In addition we also use wires made of copper, brass, phosphorbronze, nickel, monel, aluminium or higher-grade alloys such as Inconel, Incoloy, Hastelloy as well as special materials such as platinum or silver and composite wires made of metal with a plastic coating.

We use these materials to produce what is probably the most comprehensive range of metal wire cloths currently available in the market.

Knowledge of physical properties alone is not enough to decide which specifications are most suitable for which application. It is also necessary to have application experience from a wide range of industries and processes and the possibility of testing in the laboratory, technical centre and in a series of tests on-site at the customer's plant.

Wires used by PACO are only approved for production after an intensive quality check.

Weaving wires

Essential to every high-quality metal wire cloth is wire of exactly the right quality. That is why PACO has maintained close relationships with the best wire manufacturers for decades. These relationships are an essential basis for PACO's capability to fulfil the requirements placed on downstream processing and specific customer needs. All wires used at PACO undergo intensive quality testing before being cleared for production. The wire thicknesses range from 16 µm to 1.6 mm.

For special applications, wires that are not round can be processed as mesh. If required, the wires can also be finished with coatings before or after weaving.

Customising cloth rolls / added value

PACO offers a wide-ranging portfolio of further treatments for wire cloths. If a particular application necessitates it, further production technologies are also available:

- Cutting to size

- Strip cutting as a coil

- Clean annealing

- Stress relief annealing

- Vacuum annealing

- Vacuum cleaning

- Continuous cleaning

- Calendaring

- Stretching

- Stripping

- Sintering (joining of offset points)

- Plasma cutting

- Laser cutting

- Marking