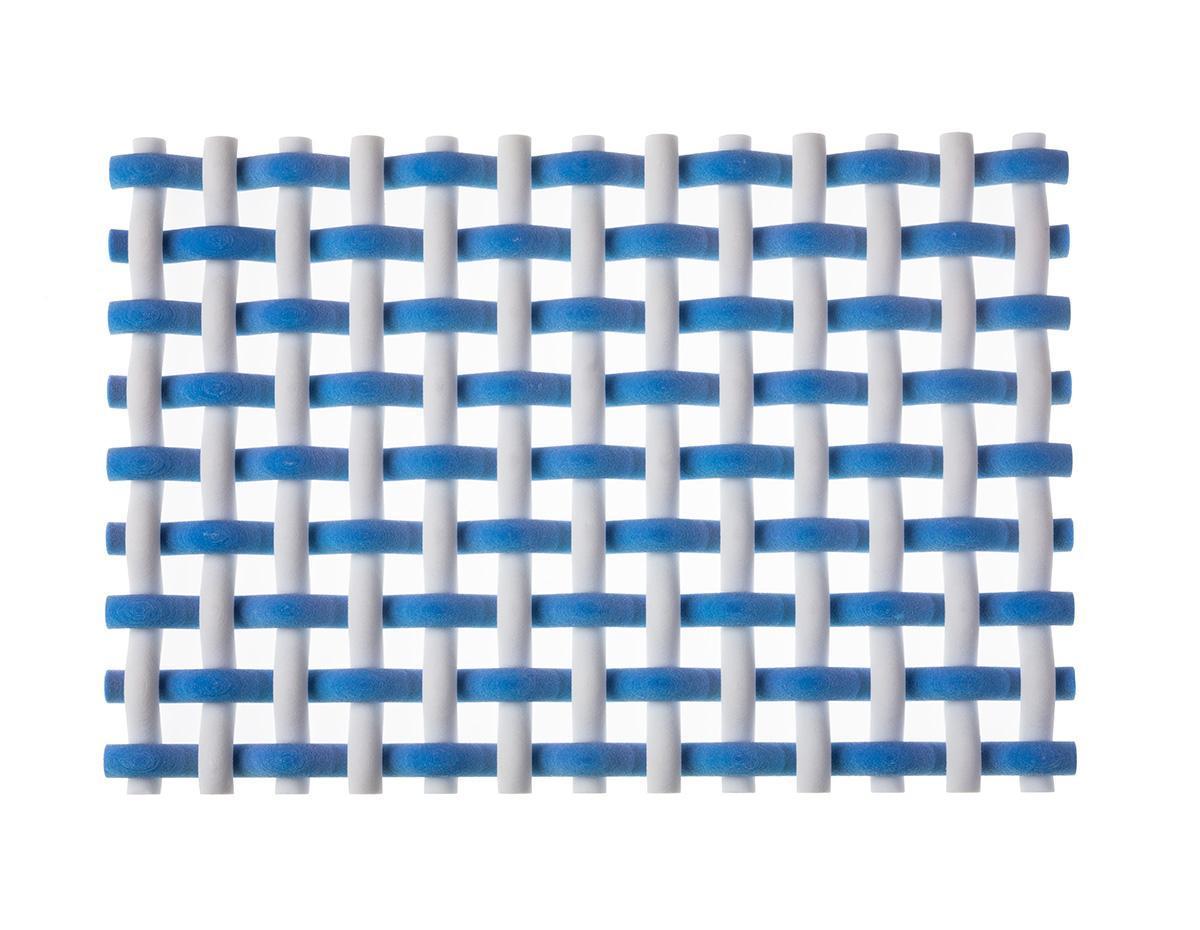

Plain or Linen Weave

Plain weave is the most commonly used weave. Its advantage lies in its simplicity enabling the tightest of wire crossings and highest precision. Every second wire is bound, with warp and weft wires constantly alternating over and under each other and fixing each other in place.

The plain weave guarantees the most precise mesh opening of all wire cloths produced in any comparable fineness range, providing clear advantages across filtration, sieve technology and screen-printing.

The linen or plain weave is the origin of all types of wire cloths. Derived from braiding, longitudinal threads (warp) and transverse threads (weft) are woven together. The weft thread runs under the warp thread in an undulating pattern, then over it the next time and so on. In this way, the threads fix each other in place allowing production of very precise mesh openings with this type of weave.

Technical data

Brochure and Data Sheet: BASICS 1

Metal Wire Cloths for Sieves and Filters

Brochure and Data Sheet: BASICS 2

Filter Cloths

Brochure and Data Sheet: BASICS 3

Screen Printing Cloths

Brochure: PACO SMART MESH

Image Brochure Screen Printing