Metal Fibre Cloths

In addition to their standard range of metal wire cloths and metal wire cloth products, PACO also supplies and further processes a wide range of nonwoven metal fibre cloths. These products that are sold under the brand names PACOFIL® and PACOPOR® are primarily used for fluid filtration and gas purification.

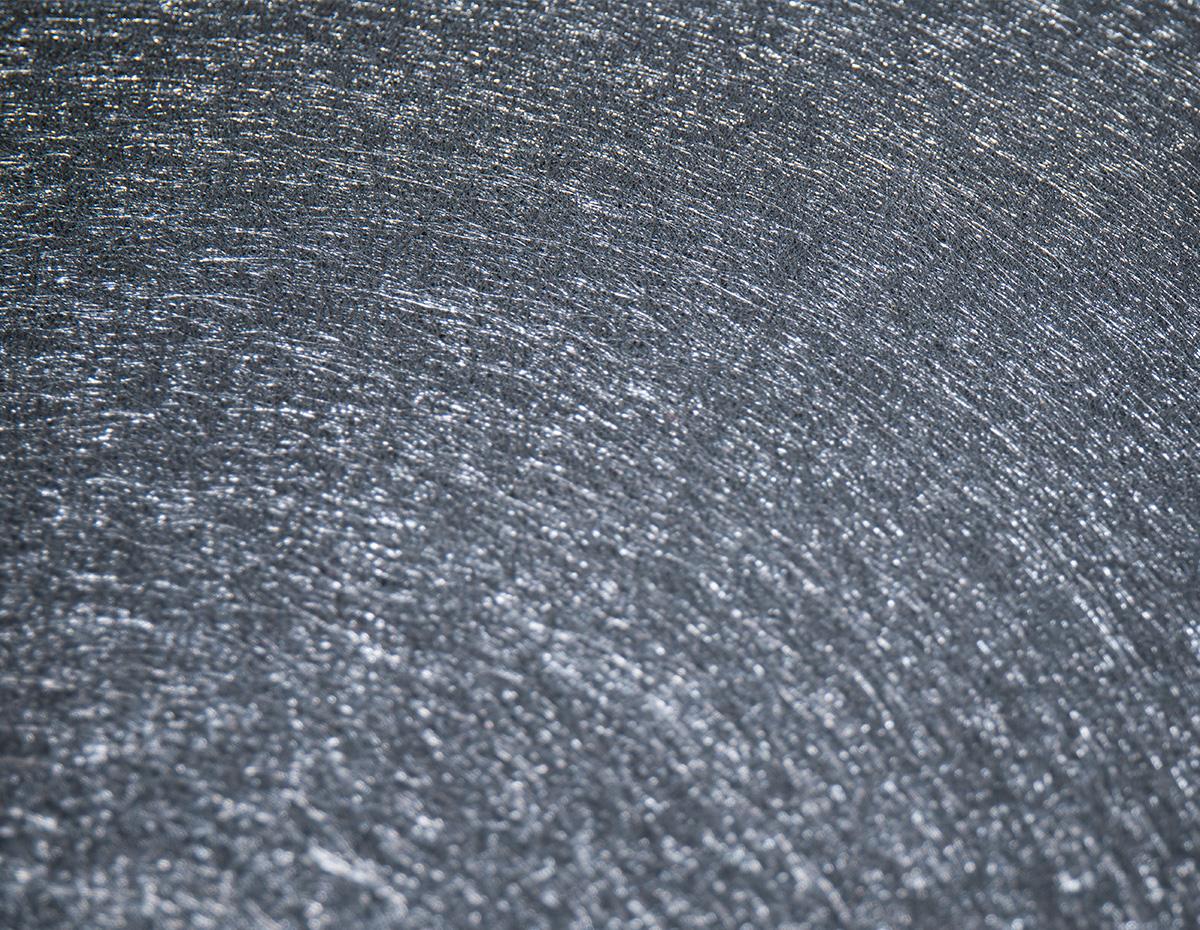

PACOFIL® and PACOPOR® are a filter medium composed of different random fibre layers (metal fibres).

Metal fibers are very thin metal wires with diameters ranging from 1 µ to 80 µ. (By comparison, a human hair has a thickness of 50 - 100 µ.) Depending on the intended use, our metal fibres and the PACOFIL® and PACOPOR® cloths made from them can be made of different materials: stainless steel, high-temperature alloys, nickel, nickel alloys and numerous others.

Based on the fibre qualities used, PACOFIL® and PACOPOR® filter media have particularly high contaminant retention capabilities. The reason for this is that the porosity (the pore volume in relation to the total nonwoven volume) has been significantly increased in recent years while maintaining the filter fineness. This extremely porous fibre structure is very flexible, particularly when it comes to optimizing filtration requirements for liquids – and increasingly also for gases (hot gas applications). The filtration integrity remains unchanged even at high temperatures and differential pressures.

PACOFIL® and PACOPOR® are the names of a sintered filter medium based on a combination of particularly fine stainless steel fibres with a fabric sintered on one side, typically with a PACOMESH 40 or 60.

This cloth performs a support function, thus increasing the mechanical load capacity, and ensures better distribution (cross-flow) between the medium and a possible substructure based on perforated plates or similar support elements.

The combination of one or more layers ultimately results in the filter medium, which is marketed under the names PACOFIL® and PACOPOR®.

Overview of the advantages of PACOFIL® and PACOPOR® filter media:

- Very easy to shape and pleat

- Corrosion and temperature resistant

- Low initial pressure drop

- Extremely high porosity

- High contaminant retention capability

- Efficient separation of gels and suspended particles due to the random fibre structure

- Longer service life

- Resistant to differential pressure

- Good backwashing properties

Technical data

Brochure: PACO Filtrenergy

The Boost in Performance and Profit

Applications

The right solution for every area

Environmental Technology

Sustainable filter systems and innovative solutions

Pharmaceuticals

Reliable cloths and filter elements for a perfect product

Food & Beverages

Years of expertise ensure first-class results

Aerospace

Innovative solutions for the aerospace sector

Energy

We support you in the energy transition

Chemicals

Outstanding quality and comprehensive expertise to satisfy the most demanding requirements

Mining

Opencast and underground mining - we are there for you!

Automotive

From design elements to safety-relevant airbag components

System Builder

Customised solutions designed to satisfy the needs of plant engineering