Technical creativity plus sophisticated engineering

Solutions have long defined each PACO product. Not just in terms of metal wire cloth, screens or filters, but also the expertise, extensive experience and understanding of customer requirements that make them work. There is no challenge that we refuse to take on and we believe that every problem can be solved. There is almost no industrial requirement that we cannot address with our products. We provide advice, development, manufacturing, packaging and distribution as well as a wide range of testing procedures in our in-house laboratory or with the help of external experts. We respond to our customers' needs with in-depth expertise and technical understanding. When developing solutions, our customers benefit from our high degree of creativity and our years of technical expertise. The spectrum ranges from the variation of an existing item to the complete redefinition of a product, including plant design and test equipment.

Reaching your goal together

The entire product development phase is supervised by an experienced team of employees with experience in research and development, manufacturing and quality management who closely work together with customer specialists to ensure that solutions are not only found and implemented faster, but are tailored to each specific application. In addition, our customers benefit from the collective expertise of an entire group of companies with individual specialisations and strengths which allows complete filter systems to be created.

There's no such thing as impossible

As a group of companies, we have in-depth process and application experience, which means that we can quickly understand the underlying issues and provide practical solutions. Regardless of whether it is a case of simple optimisation or a completely new product. Our customers benefit from PACO's expertise in the field of metal filter media and the associated products as well as the engineering know-how of HETA, a specialist for complete systems and process engineering, with a strong focus on bespoke solutions for highly demanding applications.

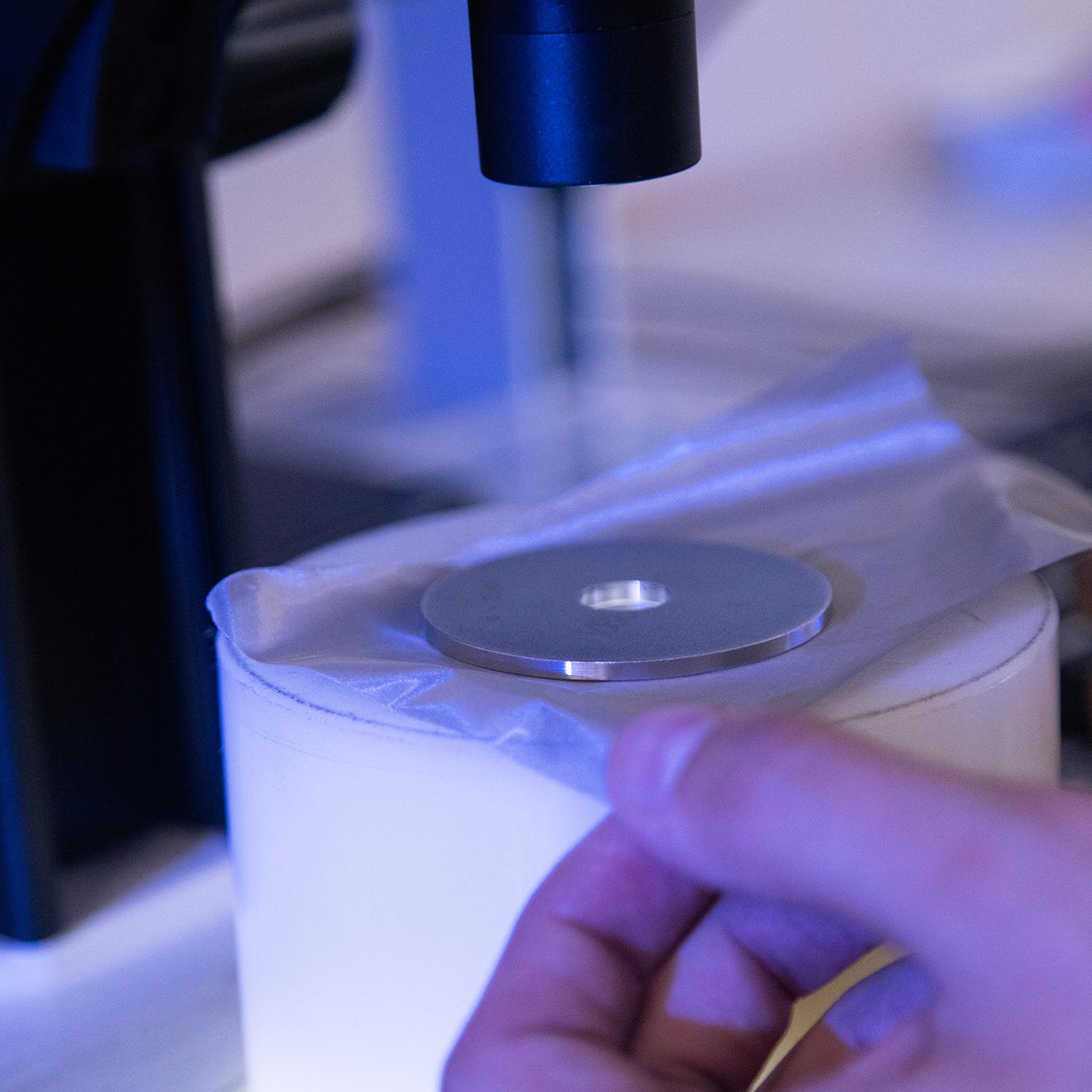

We work together to take on board the challenges and wishes of our customers as a source of inspiration for targeted solutions. In most cases, our in-house specialists quickly find the ideal solution with their technical equipment in our own technical laboratory. Where required, particularly challenging tasks are solved in cooperation with leading universities and specialised research facilities.

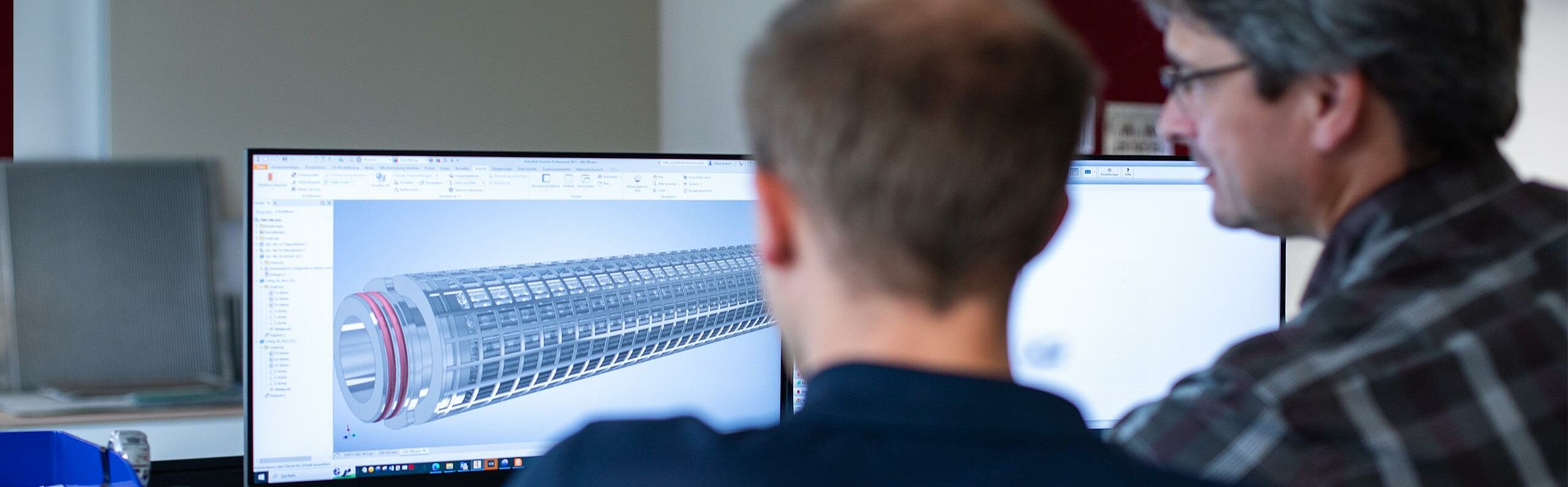

Depending on requirements, developments can be adapted to fulfil individual customer needs. For this, we have our own project management approach in accordance with IATF 16949 and ISO 9001 as well as many years of experience in the calculation and design of mechanical solid-liquid separation and the construction of pressure vessels according to AD-2000 HP0. A full service, which we also offer and carry out in house, encompassing CAD systems and simulations to virtually assist with the design.

We support our customers worldwide as a reliable partner through all process steps and accompany them from brainstorming and initial trials through to implementation, delivery, installation and on-site commissioning, as well as providing a comprehensive after-sales service.

Ensuring product quality and safety

Reliable processes are a guarantee for consistent product quality and ensure product safety. This is why we have our own in-house test laboratory with extensive equipment for physical, chemical and wire cloth or filtration-specific tests. Continuously honed methods and innovative testing systems result in increasingly accurate diagnosis and verification of product performance. We are constantly developing the associated management systems to ensure we achieve the desired results.

To fulfil this objective, we have trained our own Quality Management Representatives, Product Safety Representatives and Product Integrity Representatives as well as Product Safety & Conformity Representatives (PSCR) in accordance with VDA standards.